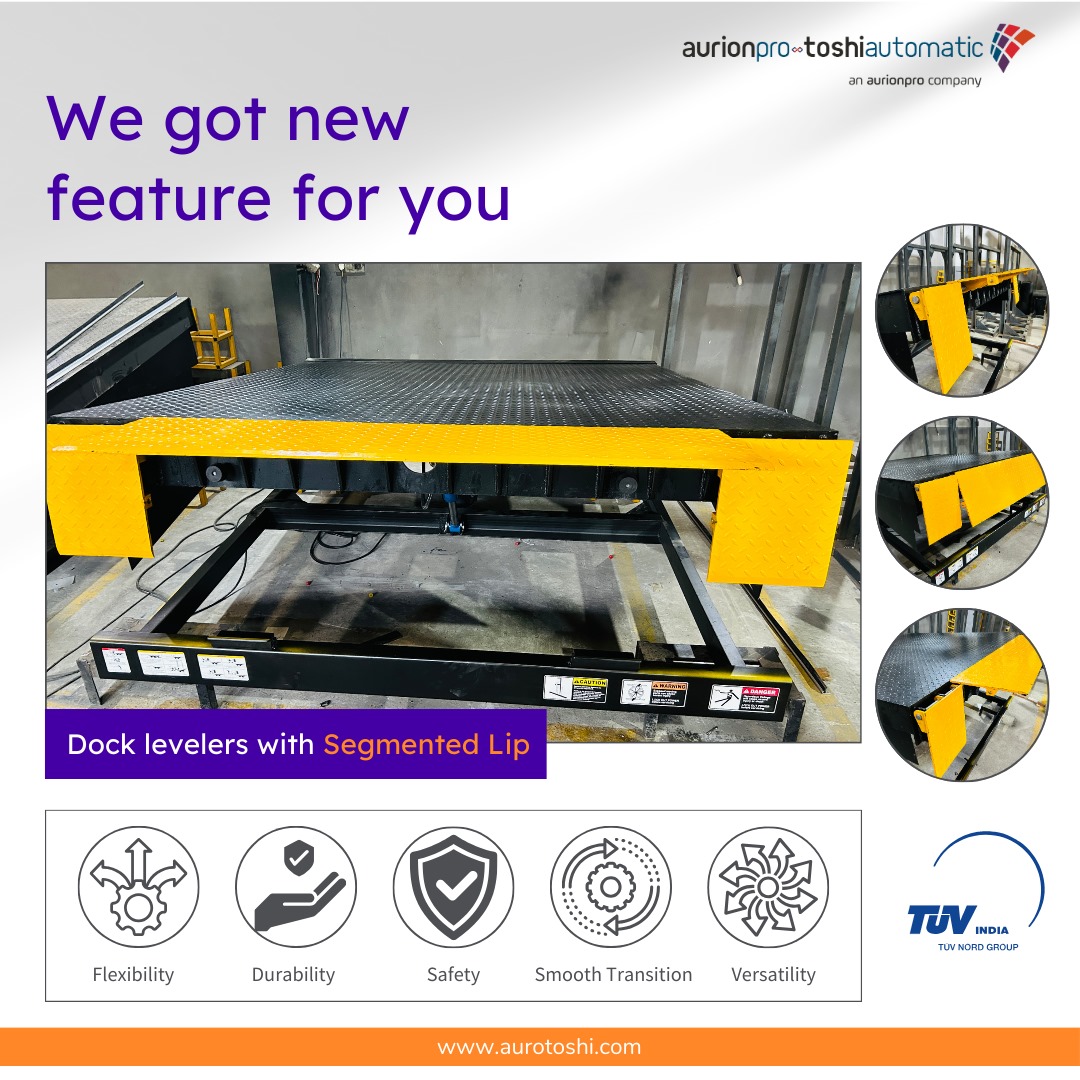

In the fast-paced world of logistics, efficiency reigns supreme. Every second saved at the loading dock translates to smoother operations and happier customers. For those who’ve witnessed the effortless dance between a forklift and a docked truck, the unsung hero behind this seamless choreography is the dock leveler. But what happens when trucks of varying sizes become part of the equation? Enter the segmented lip, a game-changer in the world of loading docks, ready to bridge the gap and ensure a smooth transition for all.

What’s a Dock Leveller?

Imagine a bridge that connects the warehouse floor to the back of a truck. That’s what a dock leveler does. It’s a platform that raises and lowers to match the height of the truck bed, creating a level surface for safe and efficient loading and unloading.

The regular lip of a dock leveler is a long, fixed ruler. It works well for some things, but only for some things. Segmented lips are like those handy multi-section rulers you might have used in school. They bend and adjust to different shapes, which is precisely what they do in a dock leveler!

Here’s the breakdown:

- Regular Lip: This is one solid piece. It is good for standard-size trucks but not for wider trailers or smaller vans.

- Segmented Lip: Multiple pieces that can move independently, like magic! They bend and adjust to fit the size of the truck bed perfectly, creating a safe and level bridge.

The Challenge: One Size Doesn’t Fit All

Regular dock levelers have a fixed-length lip, the part that extends onto the truck bed. This works well for standard-sized trucks. But what about smaller vans or wider trailers? Here’s where things get tricky.

- For vans: A regular lip might be too wide, creating an awkward gap and potential safety hazards.

- For trailers: A standard lip might not be long enough to reach the entire bed, causing instability and risking damage.

The Solution: Segmented Lips to the Rescue!

A segmented lip is a game-changer for busy loading docks that handle different vehicle sizes. It’s like a telescopic extension cord but for dock levelers! Here’s how it works:

- The segmented lip is divided into multiple sections. These sections can be hydraulically extended or retracted independently.

- For standard trucks: All segments extend outwards, creating a full-width lip for maximum support and stability.

- For vans, only the middle section extends, providing a perfect fit for the narrower bed and minimizing the van’s weight.

Benefits of Segmented Lips:

- Versatility: Handles a broader range of vehicles, from small vans to large trailers, with just one dock leveler.

- Safety: Creates a secure and level surface for loading and unloading, reducing the risk of accidents.

- Efficiency: Eliminates the need for separate dock levelers for different-sized vehicles, saving space and cost.

- Reduced Wear and Tear: By distributing weight more evenly, segmented lips can extend the lifespan of your dock leveler.

Choosing the Right Segmented Lip Dock Leveller:

- Number of segments: Most commonly, segmented lips have 2 or 3 sections. Consider the typical range of vehicle sizes you handle.

- Load capacity: The capacity of the leveler will vary depending on whether all segments are extended or just a portion.

- Operation type: Choose between manual or automatic controls for extending and retracting the segments.

- Dock Traffic and Vehicle Types:

- Analyze the typical range of vehicles using your dock. Do you see primarily standard trucks, or is there a mix of sizes?

- Knowing this will help determine the number of segments needed. Two segments suffice for occasional smaller vans, while three offer greater flexibility for wider variations.

Upgrading Your Dock Leveller to a Superhero: Segmented Lips

Maybe! It depends on the leveler’s design and the manufacturer. Here’s a quick breakdown:

- Not all levelers are created equal. Some models might be able to accept a retrofit kit for a segmented lip.

- Check the manufacturer: Contact the company that made your dock leveler. They can tell you if an upgrade is possible for your specific model.

- Consider the cost: Upgrading might only sometimes be the most cost-effective option. Depending on the age and condition of your current one, replacing the entire leveler with a pre-built segmented model could be more economical.

Here’s why upgrading might be worth exploring:

- Versatility Boost: With just one upgraded leveler, handle any size truck, from tiny vans to giant trailers.

- Safety First: Create a secure, level surface for loading and unloading, reducing the risk of accidents.

- Save Space & Money: There is no need for separate levelers for different trucks, which can free up valuable dock space and potentially save money in the long run.

Before you decide:

- Consult a professional: Get an expert opinion from a dock-level specialist. They can assess your existing leveler, recommend upgrade options (if available), and suggest the best action for your needs.

- Consider your budget: Upgrading might only be feasible for some budgets. Weigh the cost of the upgrade against the benefits it will bring to your loading dock operations.

Remember: A segmented lip can significantly improve the efficiency and safety of your loading dock. Explore your options and find the best solution to keep your operation smooth and your workers safe!

Can I add a segmented lip to my existing dock leveler?

Our team of experts can upgrade your existing AuroToshi Dock levelers with segmented lip. To know more, contact us at sales@aurotoshi.com

Segmented lips are a valuable addition to any loading dock that handles various vehicles. They offer increased safety, efficiency, and cost-effectiveness. So, next time you see a forklift effortlessly gliding onto a truck, remember the silent hero behind the scenes—the segmented lip dock leveler!